Spraytech water wire cleaning

SPRAYTECH WATER WIRE-CLEANING

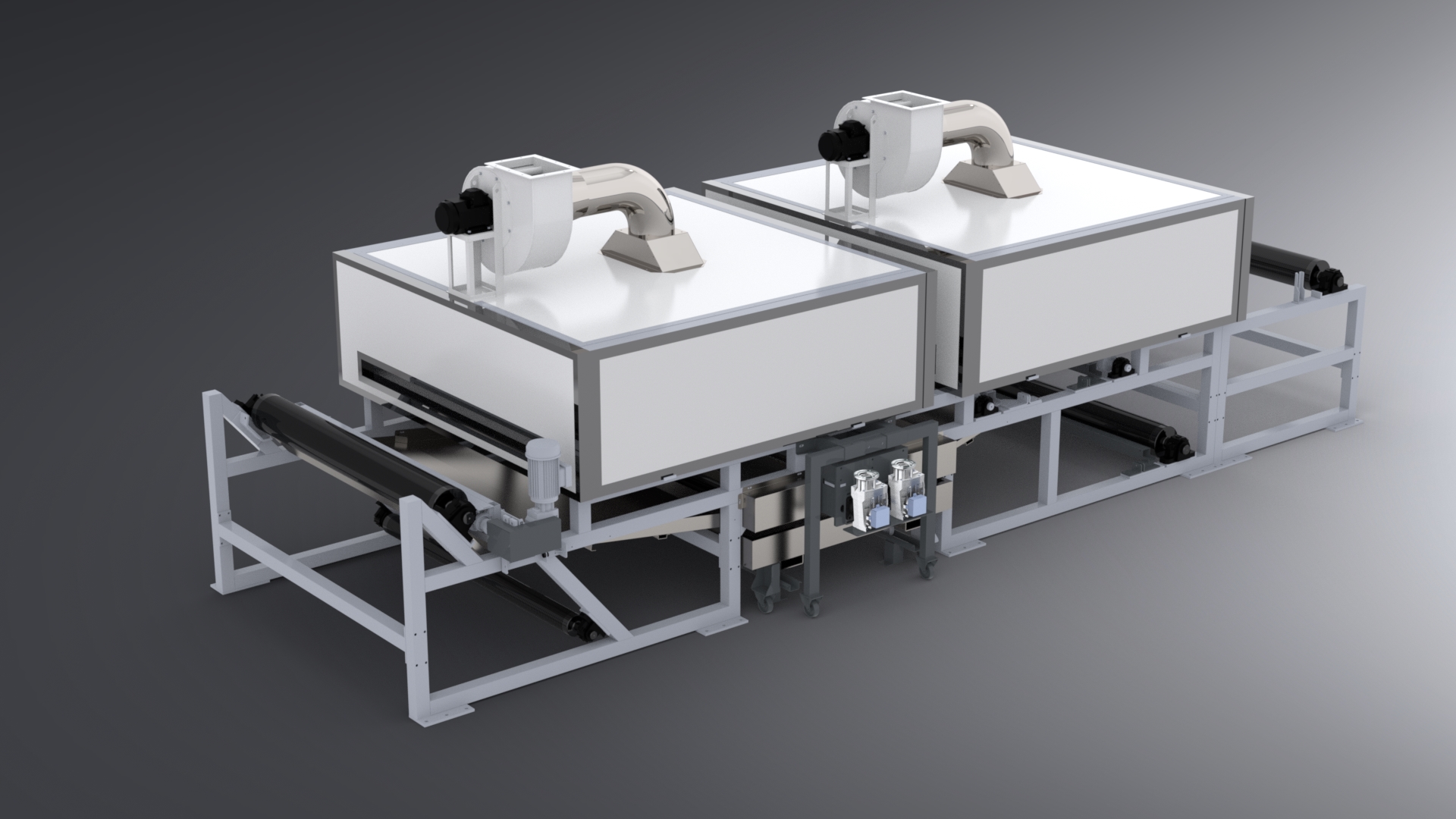

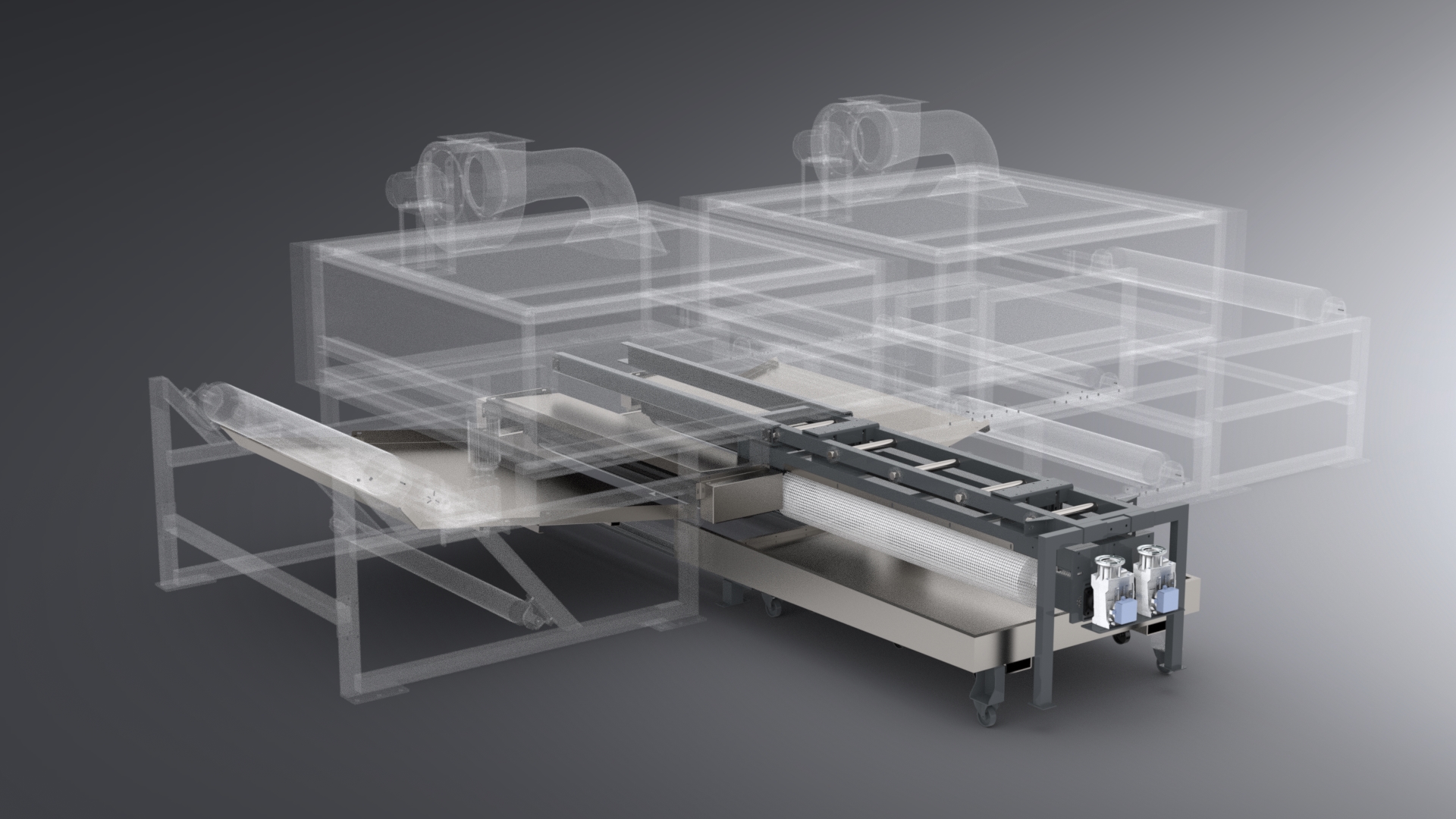

The water wire-cleaning system tackles the age-old problem of conveyor cleaning in a scientific way: first of all, the conveyors are separated, so that the wires that pass into the spray-booth (and are therefore affected by the paint products) do not also pass in the tunnel (where the products would be dried and hardened, making total cleaning impossible), but can be immediately cleaned when the sprayed product is still fresh and easier to remove completely.

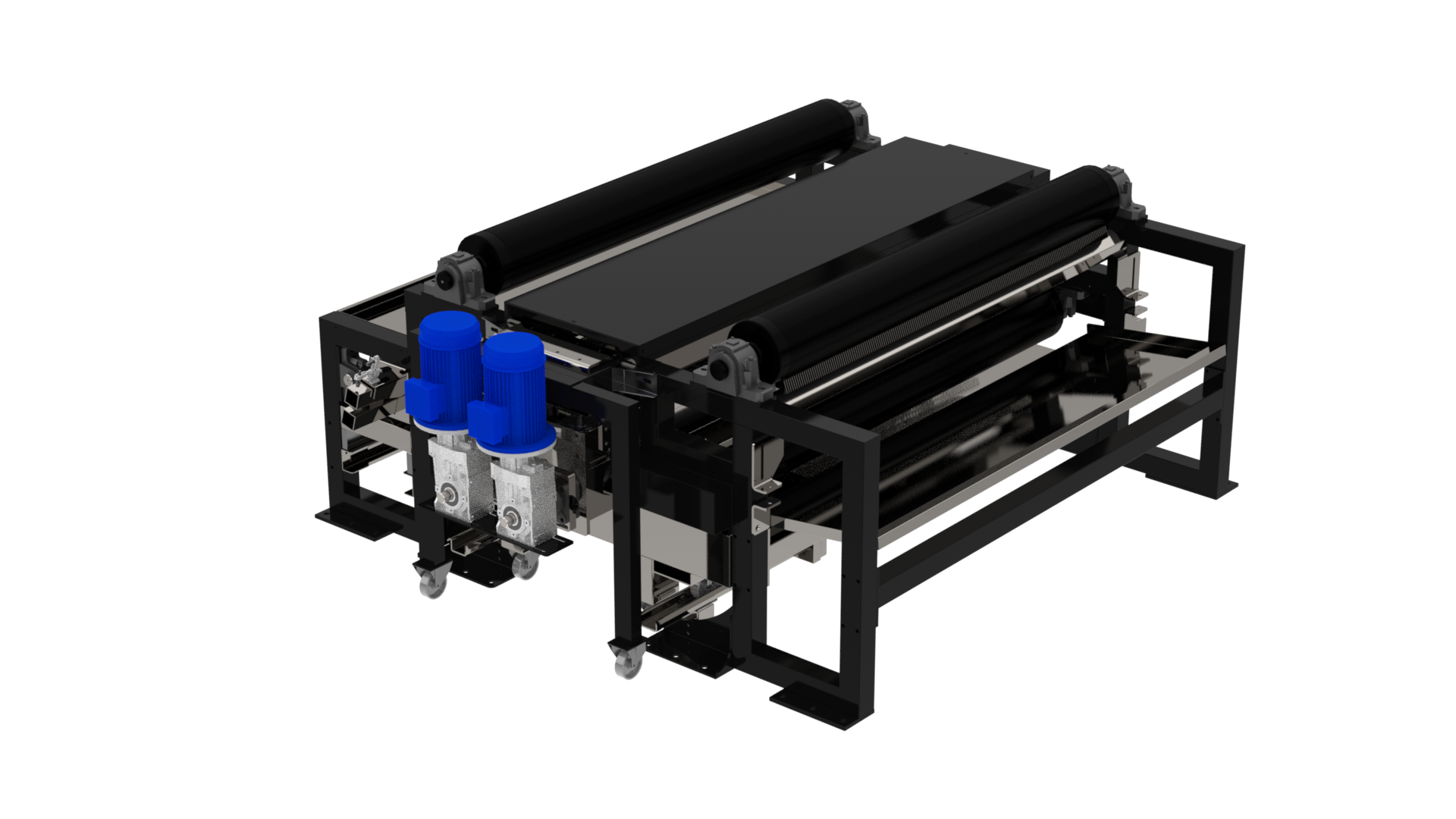

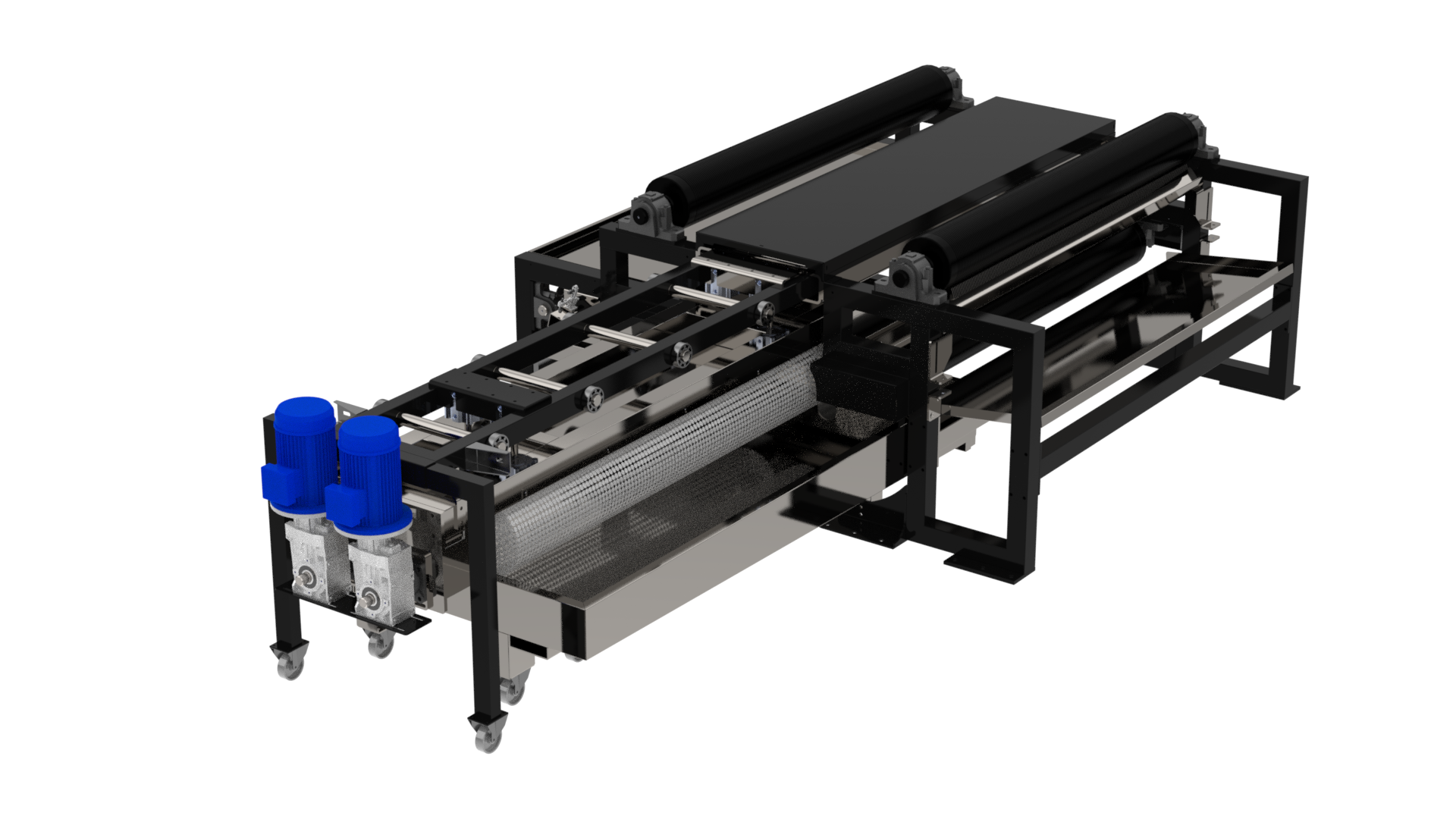

The URUS system, therefore, consists of an independent conveyor that first passes inside the booth during the painting phase and then passes into the heart of the washing system; the latter is composed of two cylindrical rotating brushes in a water bath (cold or hot), built in such a way as to effectively clean the wires on their entire surface.

The wires will then pass into a cell with hot air blades where they will be dried before returning to be used for painting completely clean and free from solid, liquid or dusty residues.

The entire brush washing system is easily removable (as well as the tank): each Spraytech product is designed to guarantee operators a high degree of practicality during the cleaning and maintenance phases.

Once out of the booth, the transport of the leather is entrusted to a second independent conveyor, never in contact with paint or dirt products, which only passes inside the drying tunnel, avoiding transporting dirt and dust inside.

The passage between the spraying conveyor and the drying conveyor is carried out by a third independent mat, thus avoiding that the leathers with fur, frills or excess parts remain entangled between the transport threads.