Spraytech gas tunnel

SPRAYTECH GAS TUNNEL

Spraytech GAS tunnels are characterized by painted panels, insulated with 80 mm mineral wool, with a system of pressurized gaskets that retain the heat eliminating the thermal jumps with the outside, thus ensuring a stable internal temperature optimal for the insulation of the leather.

The tunnels are completely modular, with cells of 3 or 4 meters; each cell is managed independently by a motor equipped with inverter with humidity and temperature controls - moreover, being entirely homemade and therefore customizable, they can be used not only for Spraytech spray-booth but also in tandem with other brands, or after the classic roller machines.

SPRAYTECH INNOVATIONS:

- Our tunnels have a gas burner for each cell, therefore every 3 or 4 meters (depending on the customer's specifications and the agreed layout); this is crucial for a high-precision and high-performance drying process: each area is adjusted according to production needs, and therefore guarantees maximum yield and consistency of temperature for the entire real length of the tunnel, without sudden changes or thermal dispersions.

- Spraytech uses batteries similar to those used in steam tunnels, retaining the heat inside and radiating it homogeneously, precisely and without unnecessary consumption.

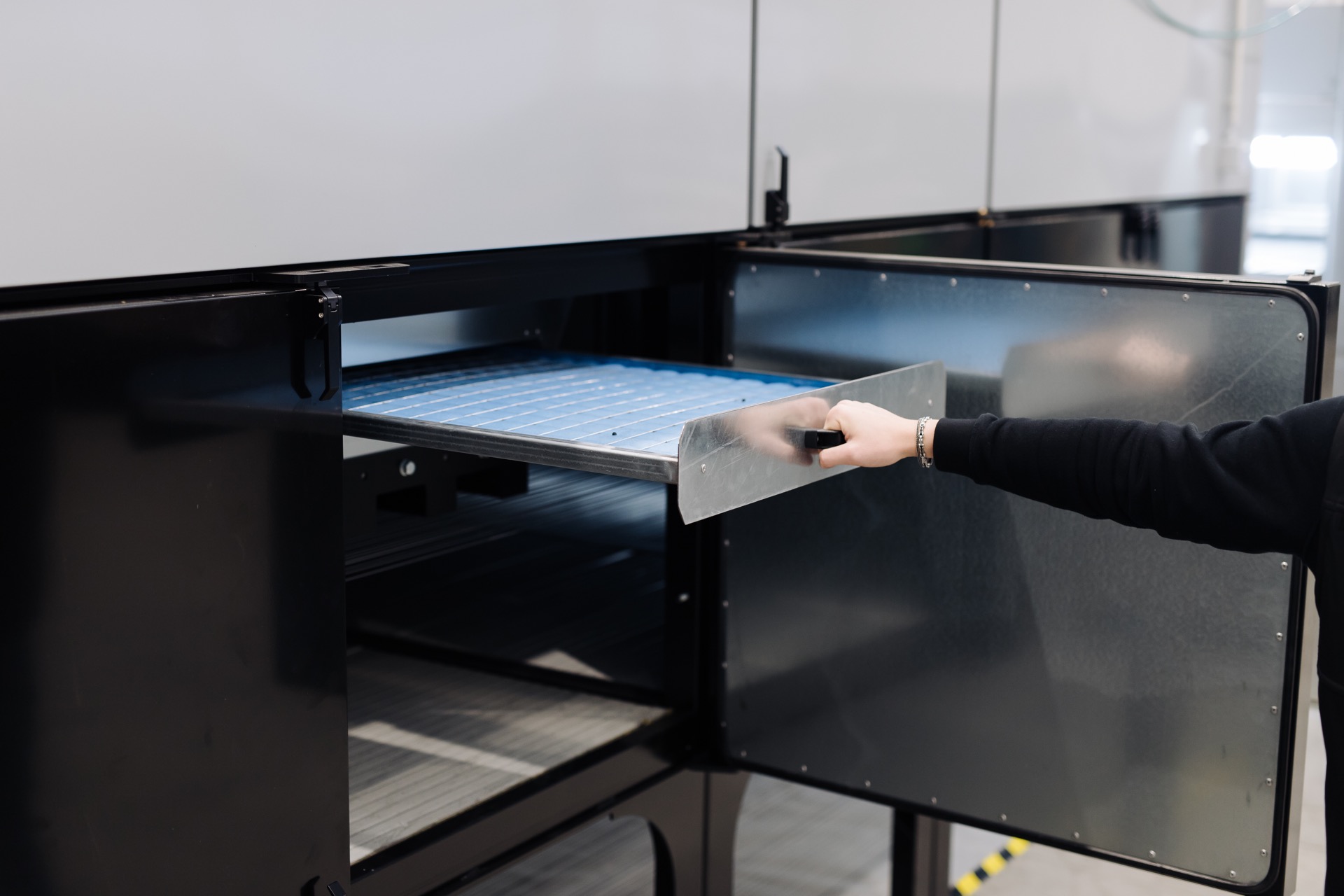

- Triple filtration system - to eliminate any contamination inside the tunnel we have positioned a filter system at the entry point of the air to be heated, another filter group before the heating coil, and a last group with removable drawers (designed for easy maintenance) before the heated air diffuser. The continuous filtration of the air at every single step guarantees total absence of particulates and dust, essential for high-level finishing.

- Dust-proof system - to further protect the hides from any possible contamination, we have spaced the conveyor belt from the bottom of the tunnel, positioning the latter closer to the ground so that - even if any external dust were to be collected - any particle would be positioned on the surface of the bottom and therefore would not be moved by the hot air circulation, eliminating any risk of deposit on a leather that is not yet perfectly dry.

- Full-hide technology - unlike our competitors, Spraytech diffusers have a real "wall-to-wall" coverage, meaning they heat the entire surface of the conveyor with the same consistency and heat - and therefore the entire surface of the leather, even on larger cuts (3400-3800mm). In addition, the hot air outlet is flat, and does not offer any surface for the deposit of dust (essential, since the outlet is another critical point where dust usually settles even with the most careful maintenance).

- Thanks to the increased height of the conveyor in the Spraytech lines (1150/1200 mm from the ground), the wires do not pass through the tunnel to return to the starting point in the first cabin, but pass under the structure avoiding any possible contact with any dust created by the movement of the conveyor or air at the bottom of the tunnel.

- This increased height also allows for additional space under the cell, inviting more comfortable and thorough cleaning.

- Energy saving: inverters that regulate each tunnel motor allow total control of consumption (kw), with automatic energy saving implemented by the Spraytech L.E.S.